Email: market@3dcnleading.com Tel: 86-0757-85221189

Binder jet 3D printer is also known as three-dimensional printing (Three Dimensional Printing), with the most extensive and mature application of 3DP technology, 3DP printing technology in the casting sand application field is becoming more and more extensive, casting sand 3D printing in the field of sample research and development, complex parts moulding, multi-species small batch and other applications have a natural advantage. CHN Leading is a well-known brand enterprise of 3DP technology, and a promoter and contributor to the industrialisation of industrial-grade 3D printing. Below, the experts of CHN Leading would like to introduce the application of 3DP printing technology in the field of casting sand mould.

1, The principle of 3DP printer printing sand mold:

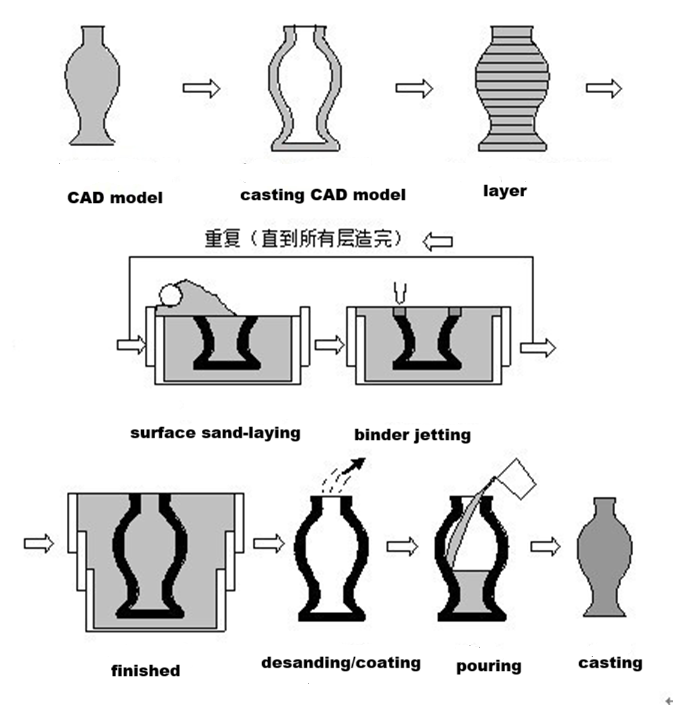

Firstly, get the casting CAD model from the CAD model of the part, layer the STL file from the casting CAD model, get the cross-section graphic, and then use the cross-section graphic information to generate control information. When moulding, let the catalyst and the fresh sand mix evenly, the piezoelectric printhead precisely sprays the binder according to the cross-section pattern,and the binder and catalyst undergo a colloidal reaction, layer by layer curing sand and stacking moulding. The binder and catalyst work together to cure the sand together, and after curing one layer, the next layer is glued, and all the cross-sectional layers are bonded together to obtain a spatial entity. Where the binder is not sprayed, the sand remains loose and is easy to remove. After cleaning out the uncured loose sand in the middle, a casting with a certain wall thickness can be obtained, and the casting can be used for pouring metal after coating or impregnating paint. (Drawing below)

2,3DP printer printing sand mold process:

01, CAD three-dimensional design to obtain the casting parts drawing, leave processing allowance;

02, sand mold design, set the pouring system;

03、Sand mold parting design;

04、Adopt CNL-3DP Slicer software to generate layer data;

05、Adopt CNL-3DP control software and CNL-3DP sand 3D printer to print the sand mold;

06、Sand mold surface cleaning, old sand recycling;

07. Sand mold/core surface coating (according to actual need);

08, Sand mold clamping.

09、Pouring metal.

010、Post-processing of casting blanks.

011, Castings processing;

012、Casting inspection.

2, The economic benefits of 3DP printer printing sand mold:

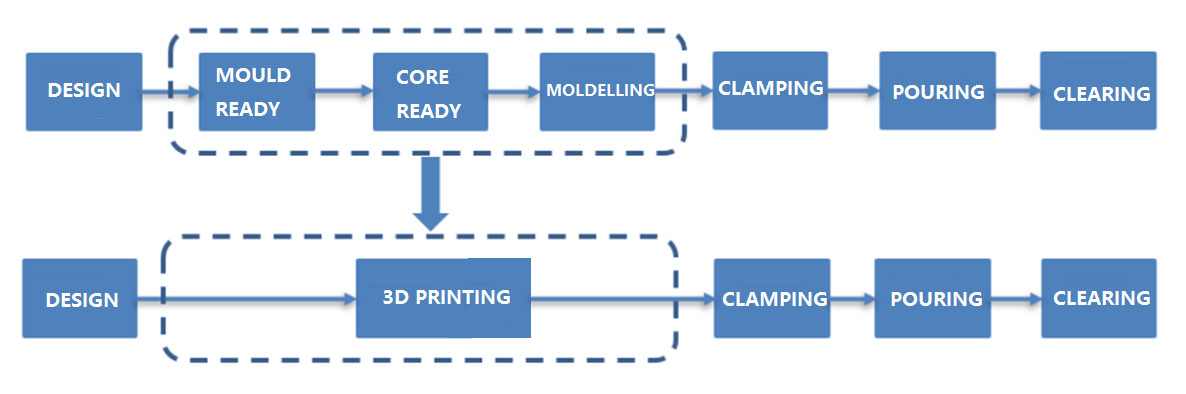

01, Because the 3DP printer printing sand simplifies the production process of sand castings, reducing the mold and mold modelling process, so, in the field of new product development, small batch production, 3D printing effectively shorten the research and development cycle, and greatly reduce the investment of all costs, has a very high value of the application of its advantages are very obvious; (as below drawing )

02, 3DP printing sand can solve the traditional processing technology can not solve the problem of manufacturing the more complex products with higher cost, so in the field of complex product manufacturing, as well as high value-added products, its advantages are very obvious;

03, Influenced by the iterative trend of skilled workers in traditional production methods, it is becoming increasingly difficult for companies to hire suitable skilled workers, but, 3D printing to reduce the dependence on artisan skills, and even zero skills on the job manufacturing, so the traditional production industry will slowly accept the 3DP printing sand industrialisation applications;

04, 3DP printing sand type can make parts integrated moulding, no need to assemble, design space is unlimited, not subject to the constraints of traditional processing and manufacturing technology, so the designers of emerging industries will like to choose 3D printing.

05, 3DP printing sand type compared with other 3D printing technology routes, has the advantages of large moulding size, fast printing speed, high efficiency and low cost.

The new generation of casting sand 3D printer developed by CHN Leading adopts the 3DP printer technology. For more information, please stay tuned with us at CHN Leading.

(Sand 3D Printer -CHN Leading)

Guangdong CHN Leading Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacturing, sales, and service of 3D printing equipment. It was founded by a team of experienced experts in 3D printing technology and digital intelligent equipment. The company has mastered core technologies in the fields of sand mold 3DP and ceramic 3DP, accumulated rich practical experience, independently innovated, and has complete intellectual property rights. Its technological achievements are among the top in the country.

CHN Leading is committed to the research and development of 3D printing technology solutions and equipment manufacturing, as well as the industrial application research and development of digital intelligent manufacturing technology. We have independently developed a new sand mold 3D printing (3D printing sand mold) technology solution and are a competitive provider of complete solutions in the field of 3DP technology.

CHN Leading Intelligent Technology Co.,Ltd

Web: www.3dcnleading.com www.3dcnlead.com

E-mail:market@3dcnlead.com; market@3dcnleading.com; sales@3dcnlead.com

Tel:+86-0757-85221189

Hot line/whatsapp/wechat: +86-18988549118

Address: No.7 Chuangye South Road, Songxia Industrial Park,Shishan Town, National High-Tech Zone, Foshan city,Guangdong Province, China

Contact: Maye

Phone: 86-18988549118

E-mail: market@3dcnleading.com

Whatsapp:86-18988549118

Add: Building A1-2, China(Gunagdong ) Robotics Integration Innovation Center,No.40 Boai Middle Road, Shishan Town,Naihai District,Foshan City ,Guangdong Province,China

We chat