Email: market@3dcnleading.com Tel: 86-0757-85221189

Changing Foam Mold Production Process, Leading Automotive Interior Mold Company Introduces Sand 3D Printer

At present, traditional sand foundries have begun to use sand 3D printing technology to replace the former wooden mold molding process, to cast metal parts in a faster and more efficient, cost-effective and energy-saving way. And in the field of foam molds, also the manufacture began to introduce sand 3D printers to change its production process.

In April 2024, NJB Media was informed that Nantong Chaoda Equipment (stock code 301186), a leading manufacturer of automotive interior molds, introduced a set of sand 3D printer intelligent production line developed and manufactured by CHN Leading for its production line. Chaoda Equipment is a leading manufacturer of automotive interior trim molds, a manufacturer that develops molds for automotive seat backs, cushions, headrests, armrests and other foam parts for automotive manufacturers; and molding and cutting molds for automotive dashboards, headliners, carpets, door panel inserts, central channels, left and right sidewalls, spare tire covers, luggage compartment interior parts, engine compartment interior parts, interior sound and heat insulation parts, and other soft-trimmed parts.

CHN Leading 3D sand printing intelligent production line

With the continuous explosion of new energy vehicles, the market demand has shown explosive growth, Chaoda equipment continues to deepen the cooperation with the international mainstream automobile OEMs and tier-one suppliers, and strives to become a globally important R & D and manufacturing base for automotive interior molds and non-standard equipment.

Part of Chaoda's products - foam molds

It is reported that in order to meet the market requires, Nantong Chaoda Equipment continuously increase the investment of equipment resources to enhance the manufacturing capacity. Now it has more than 300 sets of 3-axis CNC machining centers and more than 20 sets of large gantry 5-axis CNC machining centers, forming a strong development and manufacturing capacity. In recent years, Chaoda equipment senior leadership noticed that 3D printing technology as a new quality productivity is on the rise, after technical research found that more advanced sand 3D printing technology can be used to change the manufacturing process of its foam mold.

Due to the foam mold parts model specifications, and there is no batch of industry characteristics, before, Chaoda equipment using carving machine processing foam as a casting mold, processing cycle is long, high cost, complex parts are not good molding. Now, Chaoda equipment used sand 3D printing technology, direct printing sand as casting mold, shorten the processing cycle, save manufacturing costs, due to higher precision, sand 3D printing of casting blanks processing allowance is smaller, lower processing costs.

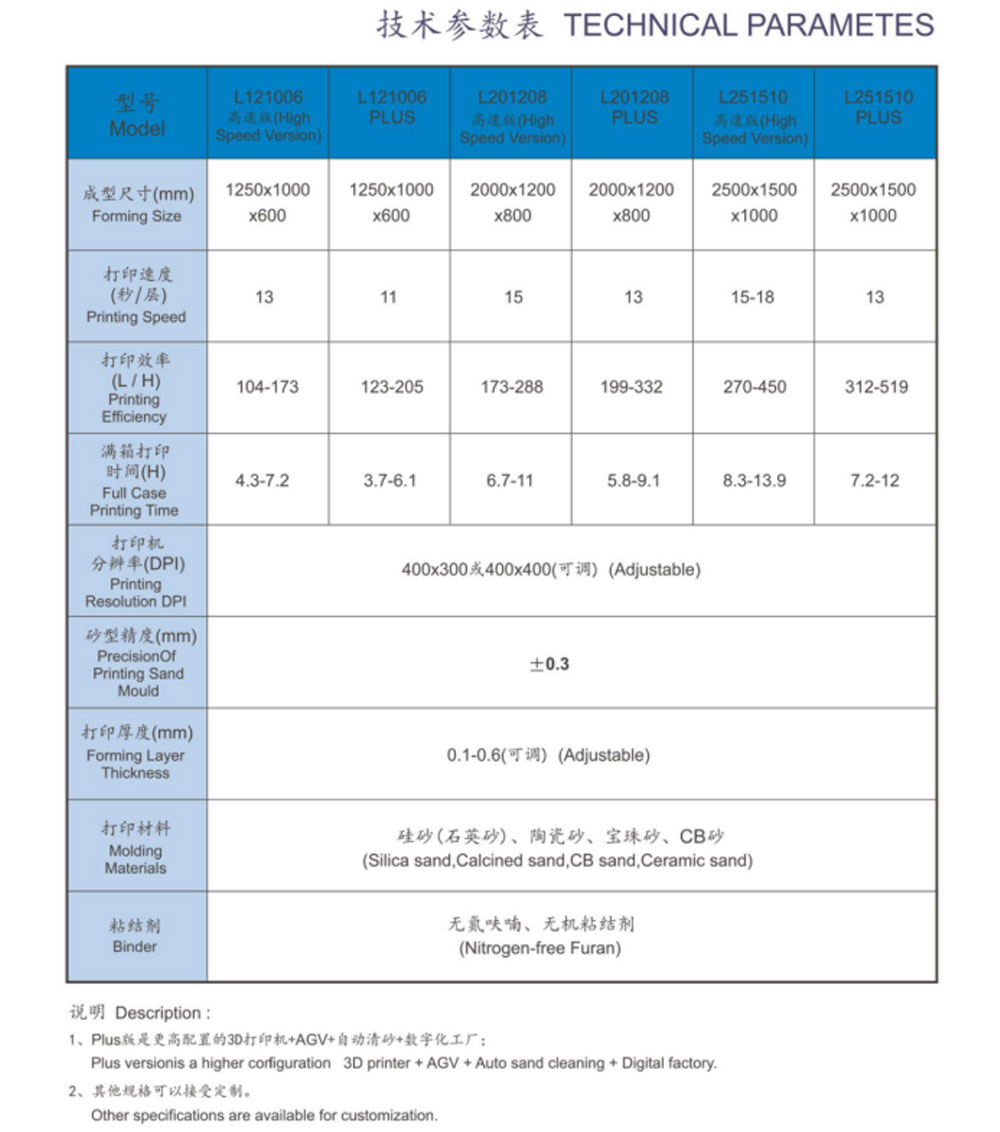

According to NJB’s knowing, the sand 3D printer intelligent production line introduced by Chaoda Equipment is developed and manufactured by CHN Leading Intelligent Technology Co., Ltd. and adopts 3DP technology, model L201208 high-speed version, with the forming size of 2,000mm x 1,200mm x 800mm, and a printing efficiency of 173-288L/H (according to the thickness of 0.3-0.5 layers), the printing efficiency Year-on-year increase of more than 60%, can easily realize the complex structure, small and medium batch casting sand production. At present, the 3D printing equipment has completed acceptance, and put into the Chaoda equipment factory normal use, stable operation for nearly one year, can completely replace the foam mold production process.

Sand Molds Printed By CHN Leading Sand 3D Printer

Bringing Change to Foam Mold Production

Sand casting production has always been an important field in modern manufacturing. With the continuous progress of science and technology, the emergence of sand 3D printers has brought new changes and opportunities for sand casting production, while 3D printing gives the manufacturing industry unlimited space for imagination!

Just finished printing the sand mold, is desanding.

Compared with traditional sand mold manufacturing methods, 3D printed sand molds have many advantages:

Easier manufacturing of complex shaped molds. Sand 3D printers make it easier to manufacture molds with complex geometries that are difficult to manufacture with traditional methods.

● An important tool in the development of new products. It can produce sand molds quickly, helping engineers test and validate them in a short period of time, which greatly shortens the development cycle of new products and reduces costs.

●Ideal for small batch production. For small batch sand molds requires, sand 3D printers have the advantages of low cost, high efficiency and high benefit, without the need to invest in mold processing and manufacturing equipment, and are able to meet the needs of diversified small batch production.

●Realization of customized production. Unique sand molds can be customized according to specific customer requirements. Whether it is shape, size or special design, it can be realized through 3D printing.

●Improved production efficiency. Rapid printing of the required molds reduces downtime and the frequency of production interruptions.

sand mold with very good surface accuracy

Mr. Wang Junheng, General Manager of CHN Leading, said, "The introduction of sand 3D printer brings higher efficiency and quality, lower manufacturing cost, and simplified and flexible production and manufacturing process to Chaoda Equipment's production, which further consolidates and enhances its market competitiveness. In the future, the two sides will also carry out more in-depth cooperation in the research and development of industrialized applications of 3D printing technology, and jointly promote the development and innovation of China's manufacturing industry."

About Chaoda Equipment

The predecessor of Nantong Chaoda Equipment, Chaoda Machinery Technology Co., Ltd. was officially founded in 2005, and the company was restructured into Chaoda Equipment Co. stock code is "301186". The company has always been taking mold design and manufacturing as the core, oriented to the domestic and international market demand, and actively expanding its business fields while enhancing the competitive advantages of its products, and is a benchmark enterprise in the foaming mold industry.

About us

CHN Leading Intelligent Technology Co.,Ltd. is a high-tech enterprise focusing on R&D, manufacturing, sales and service of 3D printing equipments, founded by a team of experienced experts in 3D printing technology and digital intelligent equipments. The founding team has been deeply cultivating in the 3D printing technology industry for many years, and has mastered the core technology in the field of industrialization of sand 3D printing and ceramic 3D printing, accumulating a very rich experience in the field of combat, and is independent innovative with full intellectual property rights. We have independent innovation and full intellectual property rights, and have applied for more than 20 national patents. CHN Leading is committed to 3D printing technology solutions and equipment development and manufacturing, and is a competitive full set of solution provider in the field of 3D printing. Its self-developed sand 3D printer adopts advanced 3D printing technology and is positioned to serve high-end user groups, capable of quickly and efficiently printing high-precision sand molds, with fast printing speed, high precision, low cost, long printhead life, high intelligence and other obvious advantages.

Contact: Maye

Phone: 86-18988549118

E-mail: market@3dcnleading.com

Whatsapp:86-18988549118

Add: Building A1-2, China(Gunagdong ) Robotics Integration Innovation Center,No.40 Boai Middle Road, Shishan Town,Naihai District,Foshan City ,Guangdong Province,China

We chat